The Instagrid One presents numerous advantages for project teams requiring portable, instant power—features that are typically associated with diesel generators. Its lightweight design (20 kg) and IP54 rating make it easy to transport to any location without the hassle of running extension leads across the site. Not only is this a convenient perk, it is also an OH&S benefit too.

While traditional power generation solutions still hold value on certain projects, the Instagrid One offers clients like Duratec reliable performance without ongoing costs or harmful emissions.

1. Environmentally Friendly: In just 2 weeks, a single Instagrid One unit reduced CO2 emissions by 321.8 kg. It also operates silently, eliminating noise, proving significant to traditional generators.

2. Portability: Unlike diesel generators that require transport and logistics, the Instagrid’s high peak power output can handle demanding power tools. This allows the team to bring power directly to their workstation, avoiding the need for extension leads from a stationary generator.

3. Efficiency: Diesel generators often run for long periods even when tools aren’t in use. Instagrid One generates power only as needed, making it a more energy-efficient option.

4. Cost-Effective: In two weeks, the Duratec team saved $262 in diesel costs. Over a year, this amounts to $6,812, not including further savings from reduced servicing, transportation, and refueling efforts.

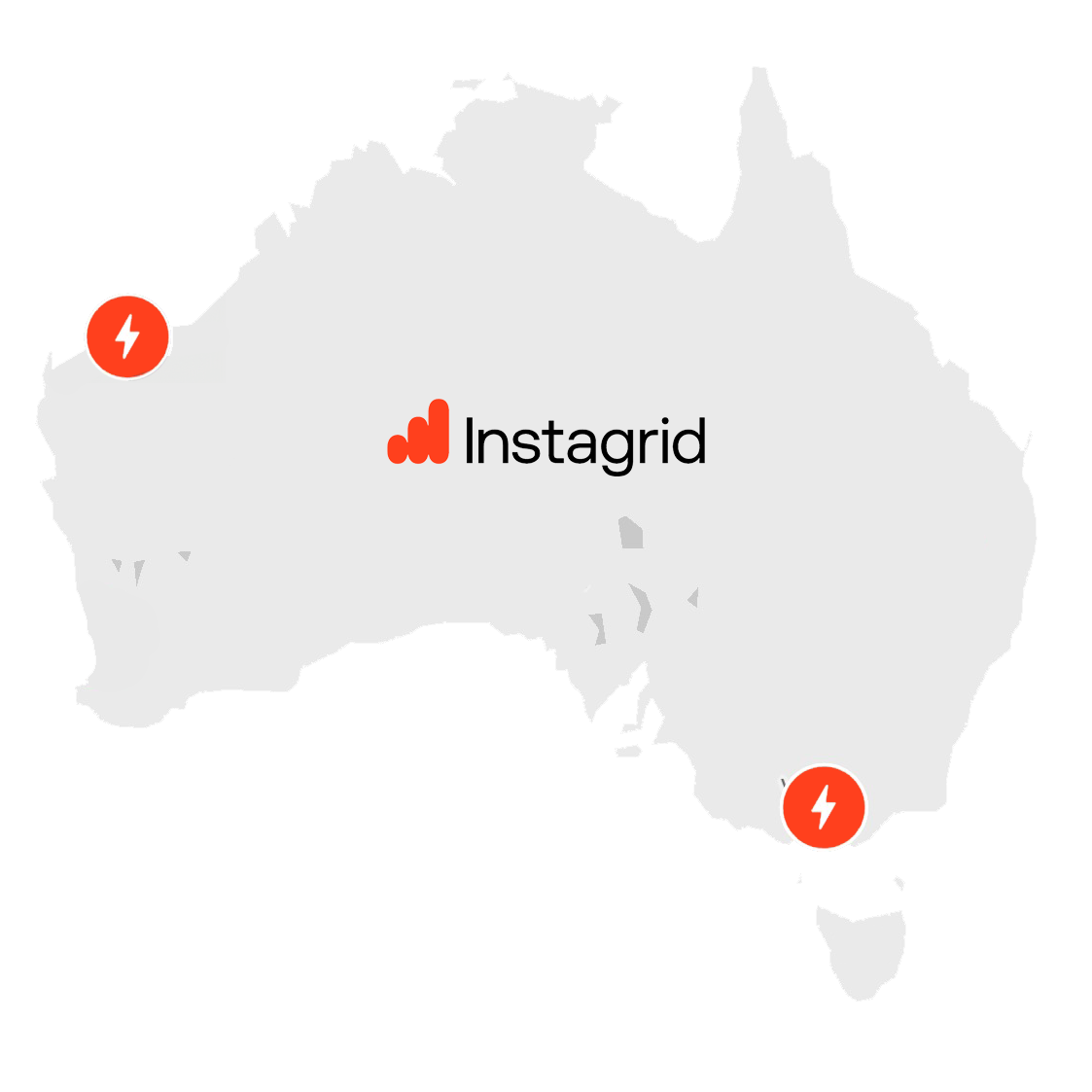

The introduction of the Instagrid One provided a highly effective alternative to traditional diesel generators by offering a portable, environmentally friendly, and cost-efficient power solution. It enabled Duratec to meet the demanding power needs of both the Melbourne and Karratha projects without the logistical complexities and high running costs associated with diesel generators. By delivering power only when needed, it improved energy efficiency and reduced CO2 emissions significantly, solving the challenge of managing intensive tasks across multiple sites without compromising performance.

APS offers cutting-edge technology and exceptional quality to elevate your projects. Enhance your productivity and achieve exceptional results. Choose the perfect power partnership and elevate your projects to new heights APS. Get in touch with us today on (08) 9455 2111.